|

Click On A Picture To Enlarge

|

||

|

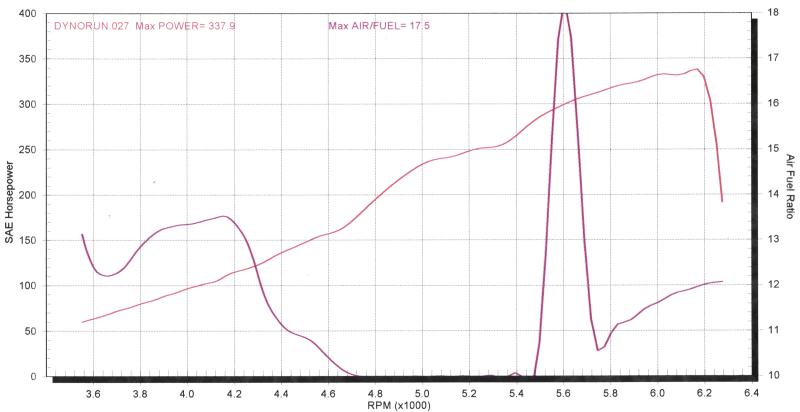

April 10th, 2006: At the dyno a quick fuel shortage under high boost took out a seal on each rotor. Compression after this was 50-50-20 on both (S4) rotors. |

||

|

|

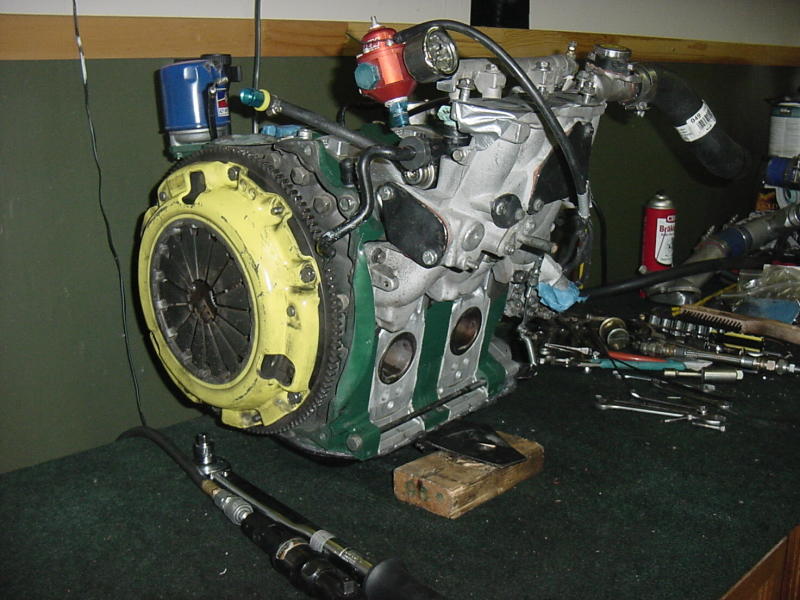

So out she comes again. | |

|

|

Those things (no longer) attached to the small block. | |

|

|

Off to Brian Cain's again for a rebuild. | |

|

|

|

I spent about 5 hrs Saturday cleaning the engine compartment, firewall and undercarriage. I put her on a rack, degreased and pressure sprayed twice, then used compressed air to dry her. Several cans of flat black Rustoleum were applied liberally and she looks better than new. Thanks very much to Jim Berg and County Line Road Import Automotive (Littleton, Colorado) for the use of their facility. |

|

|

|

May 28th, 2006, Brian rebuilt the engine, and I'm just awaiting shipment. According to Brian, we blew the corner seals off two apex seals on each rotor. He also touched up the exhaust porting, an improvement he's been using lately. The rotors and housings survived the incident without damage. While waiting for the engine to be rebuilt, I steam cleaned the tranny, then sent it to Jim Bergs. He rebuilt the shift lever box, and I can now feel the gates between gears, something I haven't had before. Also, he (hopefully) repaired the area where it was leaking fluids. I've also had time to get it back into the car again. |

|

|

|

June 10th, I finally get the engine back from Brian. I spent the rest of the day assembling it on the bench. I found the oil leak, a barely stripped thread on the turbo oil return line flange, and will helicoil it soon. Unfortunately, my "long weekend" is over, and I have to work on the engine between 12 hr shifts for several days. |

|

|

|

June 15th: I got a day off between shifts, got a hoist and put her into the engine compartment. I got most of the engine/chassis connections made, but still have a few to go. I'll be working 24 of the next 48 hours, so little time will be available to work on her. |

|

|

|

June 19th: The engine is installed, and fires up after a few adjustments. Who'da thought the clutch plate could fit in backwards? |

|

|

|

June 20th: Today I discovered it takes only 9 hours to pull the engine, flip the clutch plate and reinstall it again. I put 35 miles on her this evening. |

|

|

|

June 24th: 150 miles into break-in and she's starting to idle better. Not very strong yet, but I haven't gotten on her either. I drove her to work last night. She wants to die on the off ramps, but fires right up with a clutch drop...probably an idle issue. |